-

Lead-free Tin Powder

-

Low-temperature Tin Powder

-

Tin-Lead Tin Powder

-

High-temperature Tin Powder

Tin Powder

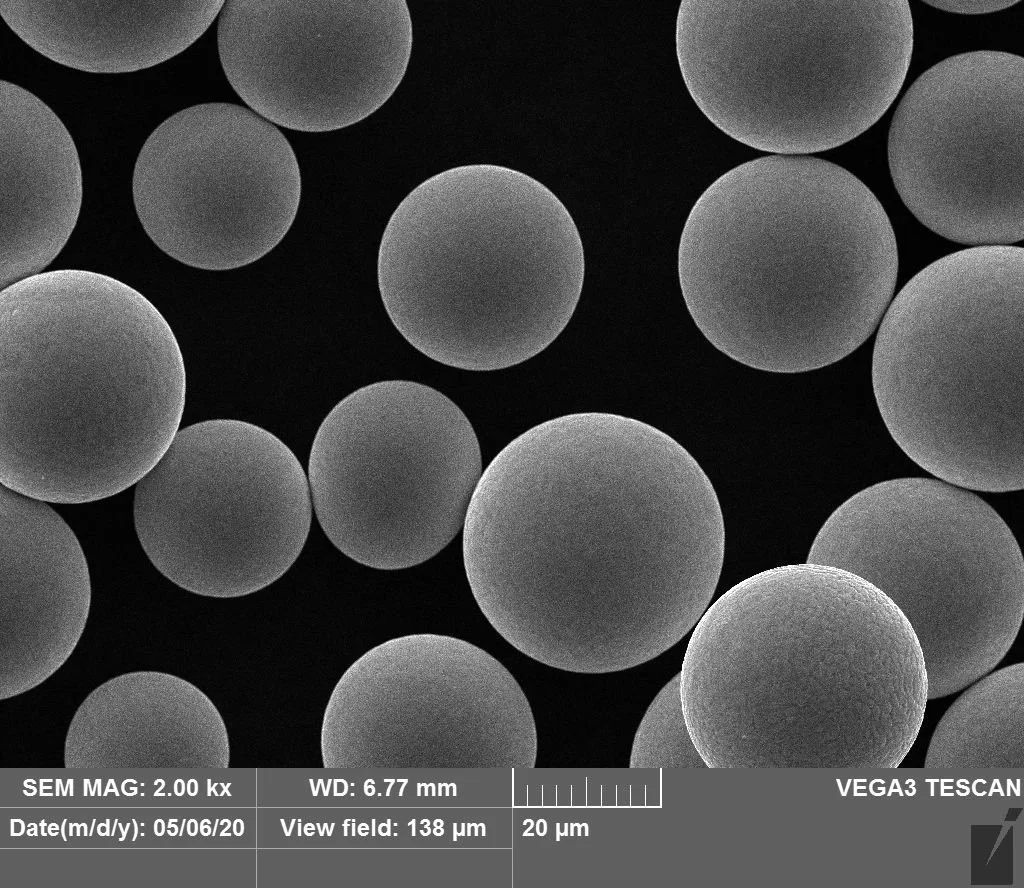

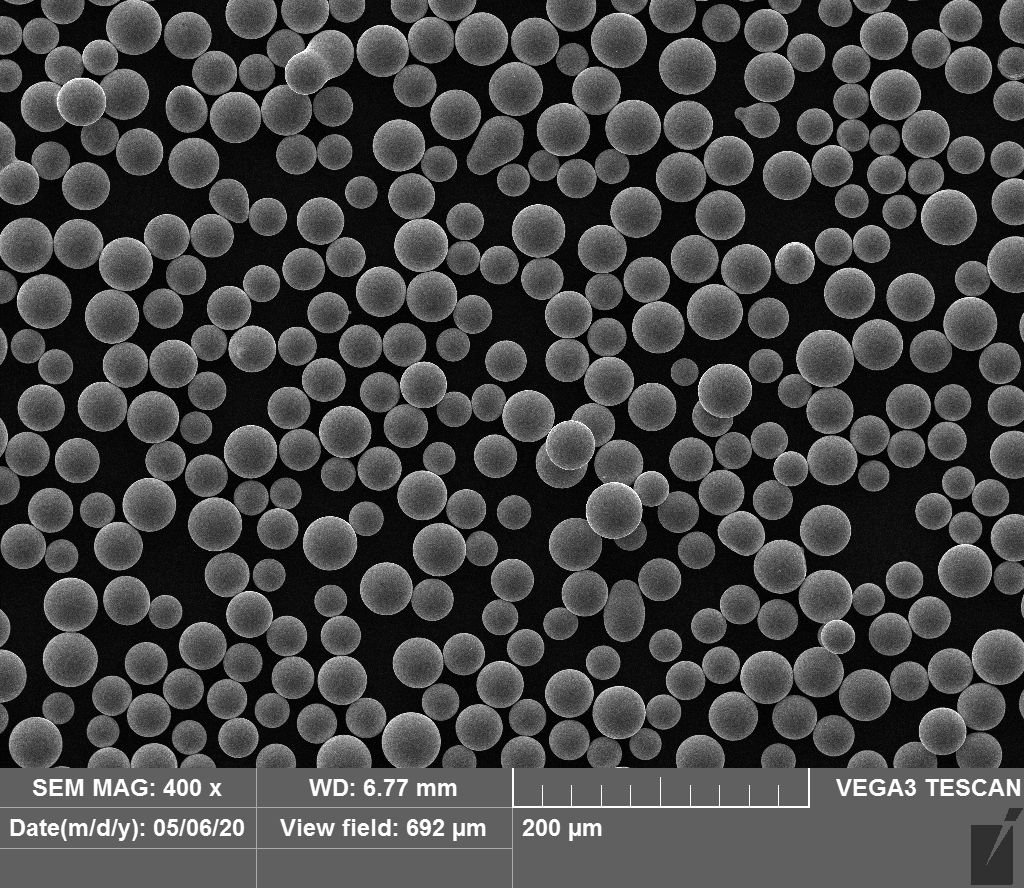

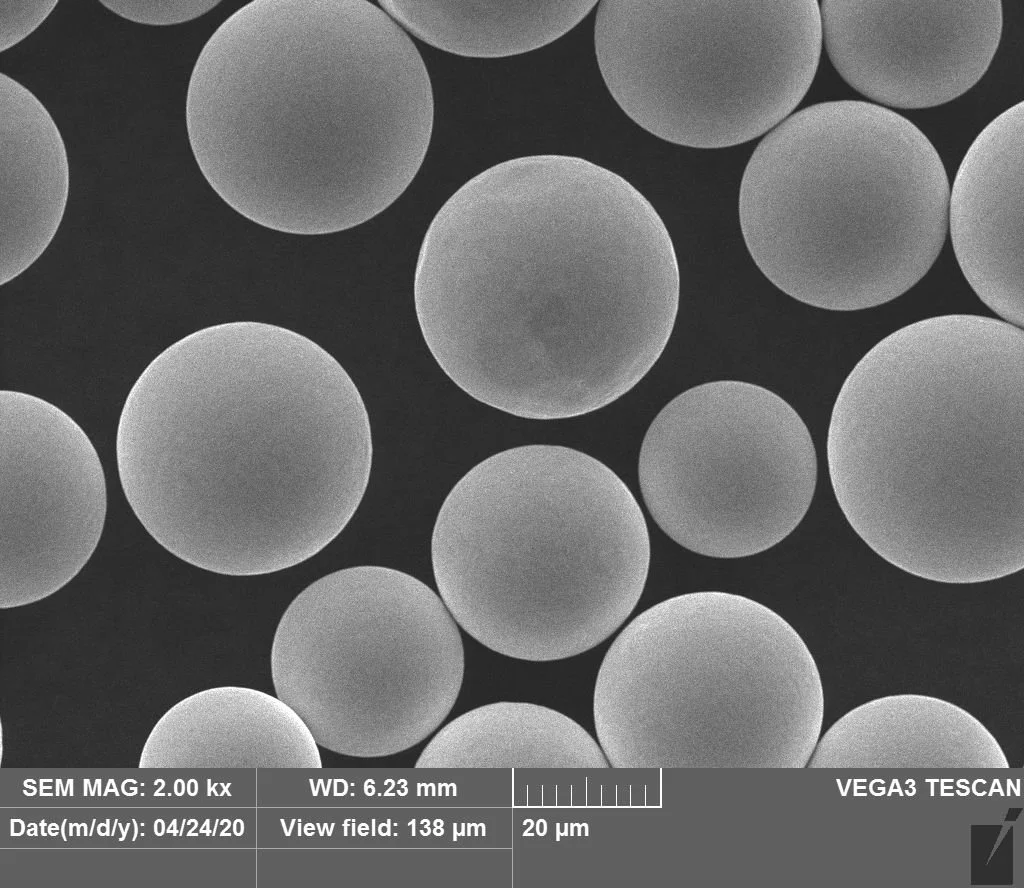

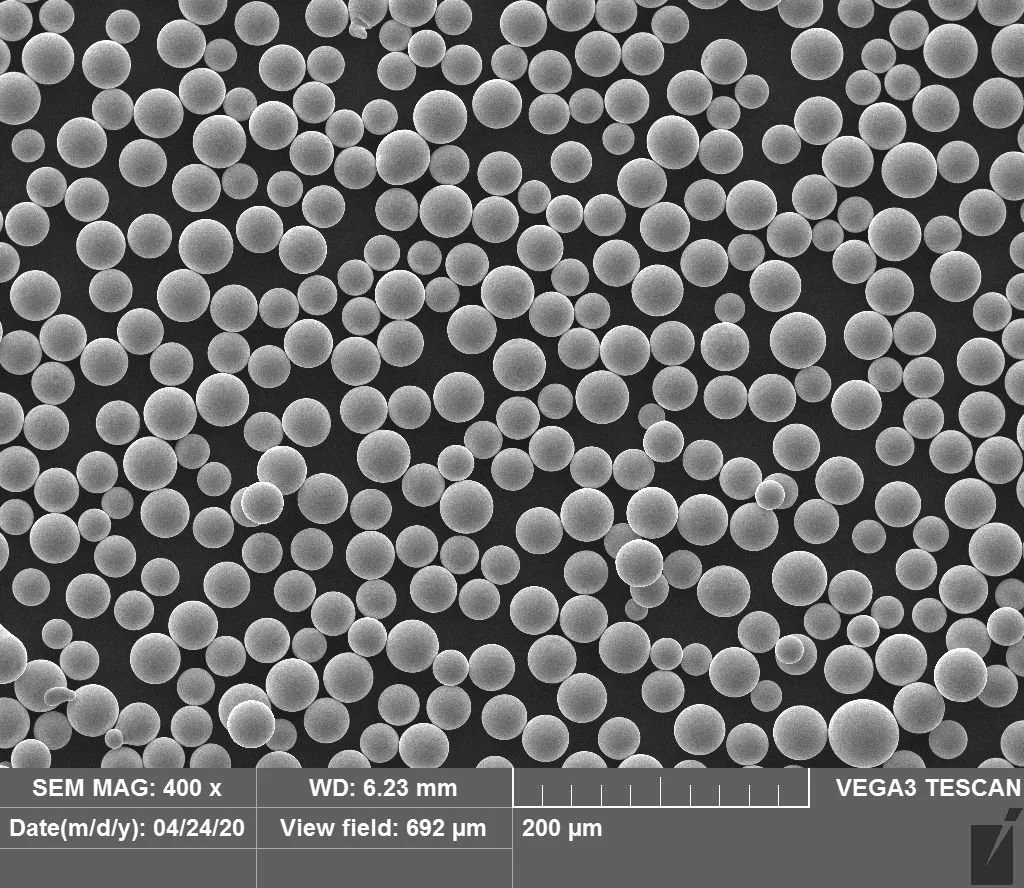

Lingsko tin powder is produced using advanced Ultrasonic Atomization Technology, featuring high sphericity, stable oxygen content, and narrow particle size distribution.

Various alloy systems and temperature grades are available to meet the requirements of SMT soldering, semiconductor packaging and precision dispensing processes.

The powder provides excellent flowability and controlled particle size, ensuring stable and reliable solder joint formation across printing, dispensing, laser soldering, and micro-joining applications.

-

KEEP UPDATING

-

KEEP UPDATING

-

KEEP UPDATING

-

KEEP UPDATING

Solder Paste

Lingsko solder paste is formulated with ultrasonic-atomized tin powder and advanced flux systems, offering excellent printability, stable viscosity, and reliable solder joint performance.

The product line covers multiple lead-free and leaded systems, suitable for SMT assembly, semiconductor packaging, LED modules, and high-power thermal management applications.

-

Features

Environmentally Friendly: Complies with RoHS Directive 2002/95/EC.

Halogen-Free: Tested according to EN14582, no halogen detected — achieving complete halogen-free formulation.

Advantages

Excellent Dispensing Performance: Smooth and uniform paste texture ensures consistent flow without clogging.

Stable dispensing performance for over 8 hours, even with 0.15 mm fine needles.High Reliability: Halogen-free and classified as IPC ROLO grade; provides excellent electrical properties and long-term stability.

Strong Process Compatibility: Ready to use after warming up — no stirring required.

Wide process window delivers high productivity, smooth solder joints, and minimal defects.Reduced Solder Balling: Optimized formulation minimizes random solder ball formation, improving first-pass yield and reducing rework.

Outstanding Anti-Slump Performance: Maintains shape after heating, producing full and bright solder joints while preventing spattering.

High Adhesion Strength: Maintains strong adhesion after reflow, ensuring solder paste remains firmly in place.

Low Residue: Leaves minimal, light-colored, non-corrosive residue with high insulation resistance and a clean surface finish.

Packaging

Net Weight per Syringe: 30 g – 1500 g (customizable upon request)

-

Product Overview

This high-temperature solder material is specifically engineered for semiconductor packaging applications. With a lead content exceeding 85 wt.%, it meets RoHS directive exemption requirements and delivers excellent process stability, solderability, and compatibility with common semiconductor packaging metals.Features & Advantages

1. Smooth, Stable Automatic Dispensing

Ensures consistent solder output with minimal variation in viscosity.

Supports high-precision automated dispensing processes.

2. Excellent Chemical Stability

Suitable for long-duration needle transfer and dispensing operations.

Meets the requirements for both dotting and printing processes.

3. Superior Solderability & Clean Residues

Produces strong, reliable solder joints with very low void rates.

Residues after soldering are easy to clean, contributing to high in-line production yields.

4. RoHS Exemption Compliant

Lead content >85 wt.% qualifies as a high-lead solder under RoHS exemption.

Designed for applications requiring high melting points and reliable metallurgical performance.

Application Scope

This product is a high-temperature, high-lead solder alloy designed for semiconductor device packaging. It is widely used in:

Power transistors

Diodes

Triodes

Rectifier bridges

Small integrated circuits

Other power semiconductor device packages

Its alloy demonstrates excellent compatibility with gold, copper, and silver, providing:

Strong solder joint mechanical integrity

High residue impedance

Stable performance in high-power and high-reliability environments

Summary

This high-lead, high-melting-point solder material is ideal for demanding semiconductor packaging processes. With exceptional flow characteristics, strong wettability, and compliance with RoHS exemption requirements, it ensures consistent, reliable performance across a variety of power device applications.

-

T510 Lead-Free, Halogen-Free Solder Paste Series

The T510 series solder paste is formulated using a special flux combined with spherical Sn-Ag-Cu alloy powder with extremely low oxygen content. It provides excellent continuous printing resolution. In addition, the flux system uses a highly reliable halogen-free activator, ensuring that even under no-clean conditions, post-reflow residues maintain exceptionally high reliability.Product Features

Stable Viscosity During Continuous Printing

The viscosity shows minimal change over time, enabling highly stable and consistent printing performance.High-Resolution Printing Capability

Suitable for fine-pitch circuits with spacing of 0.4–0.6 mm and above, producing clean and precise print deposits.Excellent Solderability

Demonstrates appropriate wetting behavior across various component locations and pad types.Flexible Reflow Compatibility

Suitable for use in standard air reflow ovens as well as nitrogen reflow systems.Reliable Performance Even at High Peak Temperatures

Maintains excellent soldering quality under high-temperature reflow conditions.

-

T300 & T800 Lead-Free High-Temperature Solder Paste Series

The T300 and T800 series solder pastes are formulated using a special flux system combined with spherical Sn-Ag-Cu alloy powder with extremely low oxygen content. They deliver outstanding continuous printing resolution. In addition, the flux adopts a highly reliable halogen-free activator system, ensuring that even under no-clean conditions, post-reflow residues maintain excellent long-term reliability.Product Features

Stable Viscosity During Continuous Printing

Viscosity shows minimal change over time, enabling very stable and consistent printing performance.High-Resolution Fine-Pitch Printing

Capable of producing clean, precise print deposits for circuits with 0.4–0.6 mm pitch and above.Excellent Solderability

Provides appropriate wetting behavior across different component locations and pad types.Compatible With Air or Nitrogen Reflow

Suitable for both standard atmospheric reflow ovens and nitrogen reflow environments.Reliable Performance at High Peak Temperatures

Maintains strong soldering performance even under high-temperature reflow profiles.

-

1. LED Leaded Solder Paste

Suitable for LED bulbs, tube lights, LED backlight modules, outdoor display panels, flexible light strips, and high-power LED applications, providing excellent soldering performance.

2. LED Lead-Free Solder Paste

Suitable for LED bulbs, tube lights, LED backlight modules, outdoor display panels, and flexible light strips, delivering high-quality soldering results.

3. LED Medium-Temperature Solder Paste

Suitable for LED bulbs, tube lights, and high-power LED applications, providing superior soldering performance.

4. LED Low-Temperature Solder Paste

Ideal for LED bulbs, tube lights, and high-power LED modules, ensuring excellent soldering quality under low-temperature processing conditions.

5. LED Die-Attach Solder Paste

Designed for LED bulbs, tube lights, and high-power LED devices, offering outstanding bonding and soldering performance.

-

Lead-Free Medium- and Low-Temperature Solder Paste Series

The D42 series solder pastes are formulated using a specialized flux combined with spherical lead-free medium-temperature Sn-Bi-Ag alloy powder or lead-free low-temperature Sn-Bi alloy powder with extremely low oxygen content. They deliver excellent continuous printing resolution. In addition, the flux employs a highly reliable low-ion halogen activator system, ensuring that even under no-clean conditions, post-reflow residues maintain exceptional long-term reliability.Product Features

Stable Viscosity During Continuous Printing

Viscosity shows minimal change over time, enabling very stable and consistent printing performance.High-Resolution Fine-Pitch Printing

Capable of producing clean and precise print deposits for circuits with 0.4–0.6 mm pitch and above.Excellent Solderability

Provides suitable wetting performance across various pad types and component locations.Compatible With Air or Nitrogen Reflow

Suitable for both standard atmospheric reflow ovens and nitrogen-reflow environments.Reliable Performance at High Peak Temperatures

Achieves strong soldering performance even under high-temperature reflow conditions.

-

1. High-Activity Rosin-Type Solder Paste for Heatsinks (Developed by LINGSKO)

This solder paste is specially formulated for heatsink applications. It exhibits excellent wettability and is suitable for soldering highly oxidized copper surfaces. After reflow, it leaves minimal residue, and the remaining residue is transparent in appearance.

2. Sn42Bi58 Alloy Compatibility

The Sn42Bi58 alloy is compatible with a wide range of reflow equipment, including infrared, vapor phase, and hot-air convection systems.

The ideal heating rate is 2.5–3.0 °C/sec (most components have a maximum allowable heating rate of 4.0 °C/sec).The Sn42Bi58 alloy is available in:

Type 2 powder: 75–45 μm

Type 3 powder: 45–25 μm

Type 4 powder: 38–20 μm

Type 5 powder: 25–15 μm (for precision dispensing applications)

-

The LED series solder paste is formulated using a specialized flux combined with spherical Pb-Sn alloy powder with extremely low oxygen content. It delivers excellent continuous printing resolution. In addition, the flux system utilizes a highly reliable low-ion halogen activator, ensuring that even under no-clean conditions, the post-reflow residues maintain outstanding long-term reliability.

Stable Viscosity During Continuous Printing

The viscosity changes very little over time, enabling highly stable and consistent printing.High-Resolution Fine-Pitch Printing

Capable of producing clean, precise print results for circuits with 0.4–0.6 mm pitch and above.Excellent Solderability

Provides suitable wetting behavior at various component locations and pad types.Compatible With Air or Nitrogen Reflow

Can be used in standard atmospheric reflow ovens as well as nitrogen reflow environments.Reliable Performance at High Peak Temperatures

Achieves strong soldering performance even under extremely high peak reflow temperatures.